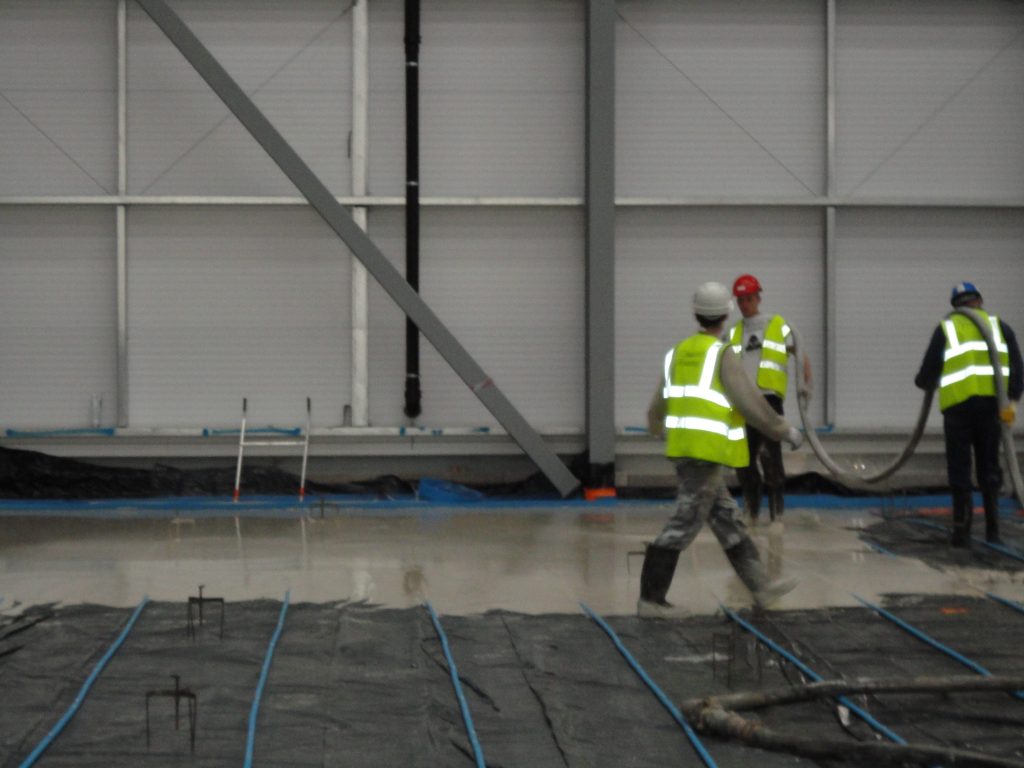

Liquid Flowing Screed

Historically many building projects have predominantly use standard sand and cement screeds however Liquid Flowing Screed is fast becoming the product of choice for many architects and developers because it has many advantages in comparison some of which include:

Speed of installation, a three man team can usually install 150m2 of sand and cement screed in a day, the same size team can install around 600m2 of liquid screed.

Due to a higher flexural strength liquid screed can be installed thinner thus reducing cost, speeding up drying time and reducing the risk of cracking in comparison to sand and cement screeds.

In some part of the country building control have found it acceptable to install a floor build up of:

Hard Core

Damp Proof membrane

Insulation

50mm Liquid screed

This means that the concrete base is not required and therefore reduces the build cost.

The screed can be used on top of under heating at a total depth of 50mm, minimum cover to pipes is 25mm.

- Foot traffic: 48 hours

- Loading: 7 days

f the building is maintained at 20 Degrees C based on 50mm depth the floor will reach 60% RH at 28 days.

After 7 days the floor can be force dried or have DPM systems applied to reduce the time required to lay floor finishes.

Midland Flooring can supply and install the insulation, underfloor heating and the liquid flowing screed.